Process Of Wire Drawing

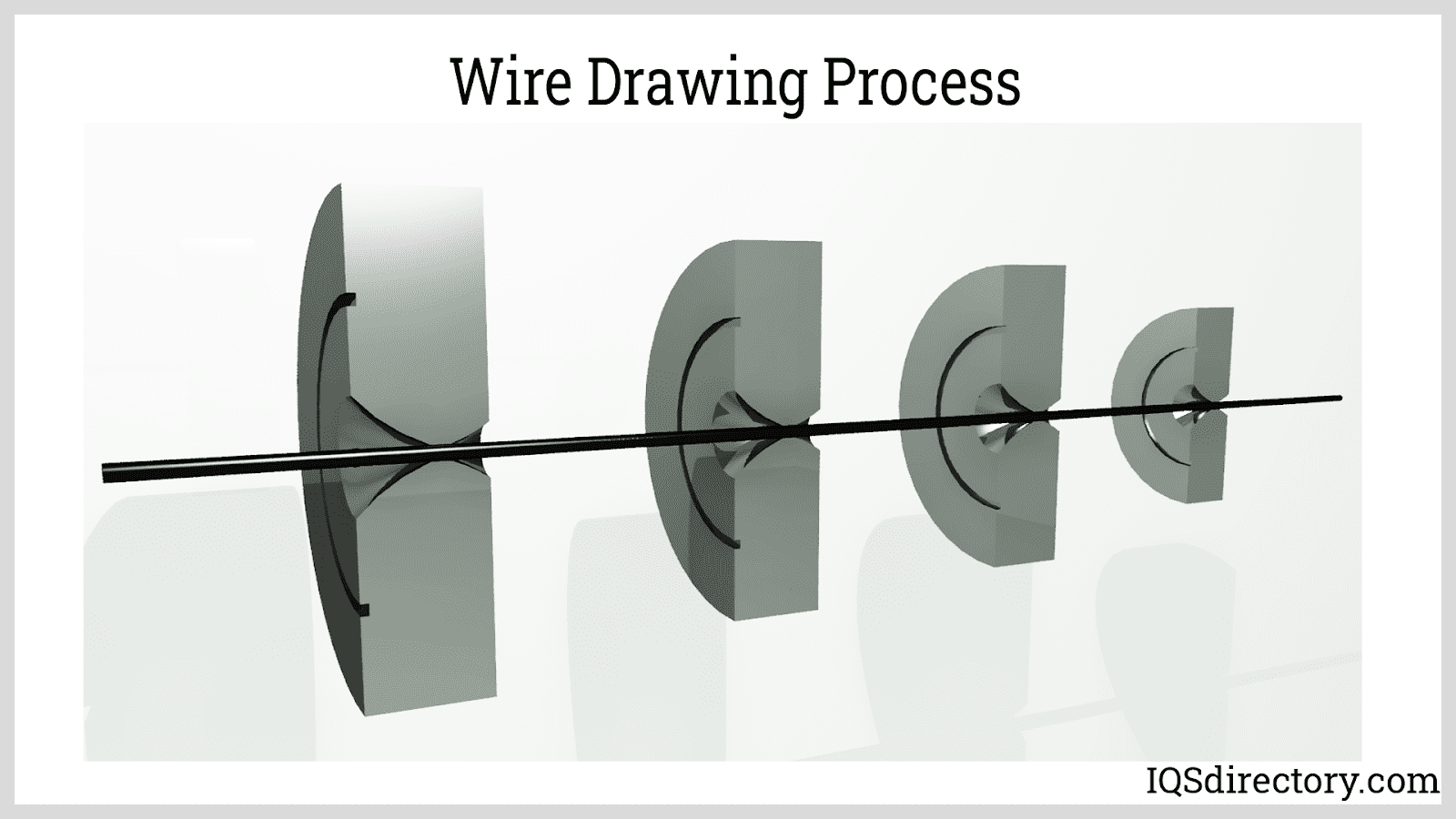

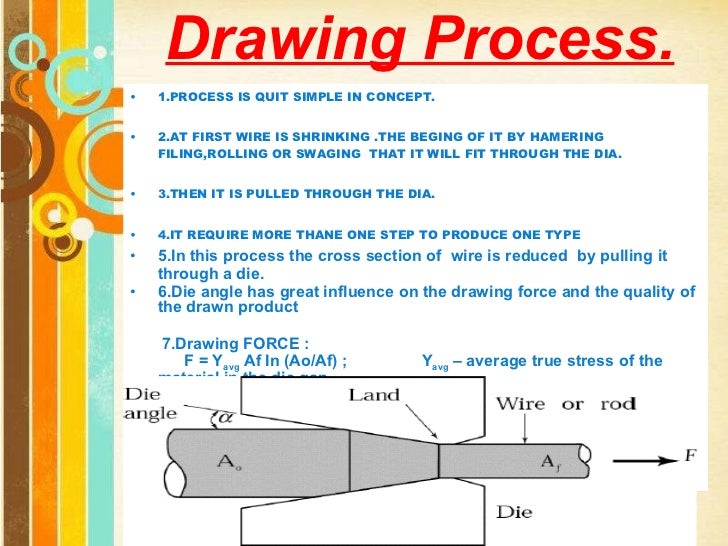

Process Of Wire Drawing - Web wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. From roughing to winding and braiding, each stage of the process has lubricants specifically designed to optimize efficiency and the quality of the final product. Let us discuss more details about this metalworking process in detail. This technique is widely used in various industries, including manufacturing, jewelry making, and electrical wiring. Web wire drawing consists of pulling a metal wire through a small circular opening called a die. Modern wire drawing process is similar to the one used centuries ago, however, significant developments have taken place in the machines and the dies. What is wire drawing, tube drawing and making? Web 1.analysis of wire drawing: Each hole on a drawplate is marked with a number. Consider the drawing of a wire through a conical shaped draw die, as shown below, schematically: The tandem wire drawing machine made in 1880. Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages. The products are characterized by high strength because of strain hardening. Soap is used for lubrication. Web tadal cu and tadalfil, drawing lubricants cromogenia units’ lubricants are specially formulated to cover all phases. Soap is used for lubrication. This technique is widely used in various industries, including manufacturing, jewelry making, and electrical wiring. Web 1.analysis of wire drawing: Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages. 1.1 analysis of wire drawing. Web wire drawing, making of wire, generally from a rod or bar. Wire drawing is a continuous process. Let us discuss more details about this metalworking process in detail. Forging is the plastic, or permanent, changing of a metal shape. Drawing will also increase the temper, or hardness, of the wire. Drawing will also increase the temper, or hardness, of the wire. Web 1.analysis of wire drawing: Web this lecture describes the fundamentals of wire drawing including working principle, mechanism, calculation of various parameters, advantages, disadvantages. Modern dies are made out of tungsten carbide, ceramic, diamond or hard alloy. Similarly rods are drawn from steel rounds of larger diameters. The products are characterized by high strength because of strain hardening. The process can be used to create wires of different sizes and shapes, depending on. Wire drawing is a continuous process. Web wire drawing is a fundamental metalworking process that involves elongating a wire by pulling it through a series of dies, each progressively smaller than the last. Bar. The block, made to revolve by an electric motor, pulls the lubricated rod through the die, reducing it. Wire drawing is a process that involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. Modern wire drawing process is similar to the one used centuries ago, however, significant developments have taken place. Drawing wire through a drawplate changes its shape and reduces its diameter while simultaneously lengthening the wire. This results in a stretching or elongation of the material along with a reduction in cross sectional area. The subsequent drawing die must have smaller bore diameter than the previous drawing die. Consider the drawing of a wire through a conical shaped draw. Forging is the plastic, or permanent, changing of a metal shape. Consider the drawing of a wire through a conical shaped draw die, as shown below, schematically: Soap is used for lubrication. From roughing to winding and braiding, each stage of the process has lubricants specifically designed to optimize efficiency and the quality of the final product. Web understanding the. Modern dies are made out of tungsten carbide, ceramic, diamond or hard alloy. Web 1.analysis of wire drawing: Some of the important terms associated with wire drawing are to be understood first. Forging is the plastic, or permanent, changing of a metal shape. Web wire drawing is an cold working process. Web technology of wire drawing: Web stainless steel wire drawing is a metalworking process that involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. The finished wire is coiled onto a motor driven block. This results in a stretching or elongation of the material along with a reduction in cross sectional. The tandem wire drawing machine made in 1880. In this technical post, we will delve into. Soap is used for lubrication. Similarly rods are drawn from steel rounds of larger diameters. Consider the drawing of a wire through a conical shaped draw die, as shown below, schematically: Some of the important terms associated with wire drawing are to be understood first. Modern dies are made out of tungsten carbide, ceramic, diamond or hard alloy. The pulling force is limited by the strength of the material: The finished wire is coiled onto a motor driven block. This process involves reducing diameter of thick wire by passing it through a series of wire drawing dies with successive die having smaller diameter than the preceding one. Web wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. It is an operation to produce wire of various sizes within certain specific tolerances. In metal works, wire drawing and tube drawing is a stretching of a metal or plastic or even glass material to the desired shape in continuous products such as wires and tubes. This process is a type of forging. Web 1.analysis of wire drawing: It is an ancient plastic processing technology.

Wire Drawing Process(Parts And Working) YouTube

What is wire drawing process? Wire Drawing Machines Mashtronics

Wire Cloth What Is It? How Is It Used? Materials, Types

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing

PPT STEEL WIRE MANUFACTURING PowerPoint Presentation, free download

wire drawing setup

1 Forces acting in different regions of wire drawing process

Wire Drawing Process YouTube

Wire drawing ppt

What is wire drawing process? Wire Drawing Machines Mashtronics

Web Understanding The Basics Of Wire Drawing.

Drawing Will Also Increase The Temper, Or Hardness, Of The Wire.

Pull Too Hard And The Metal Will Break.

Bar Drawing Is Done In Single Draft.

Related Post: