Drawing Stamping

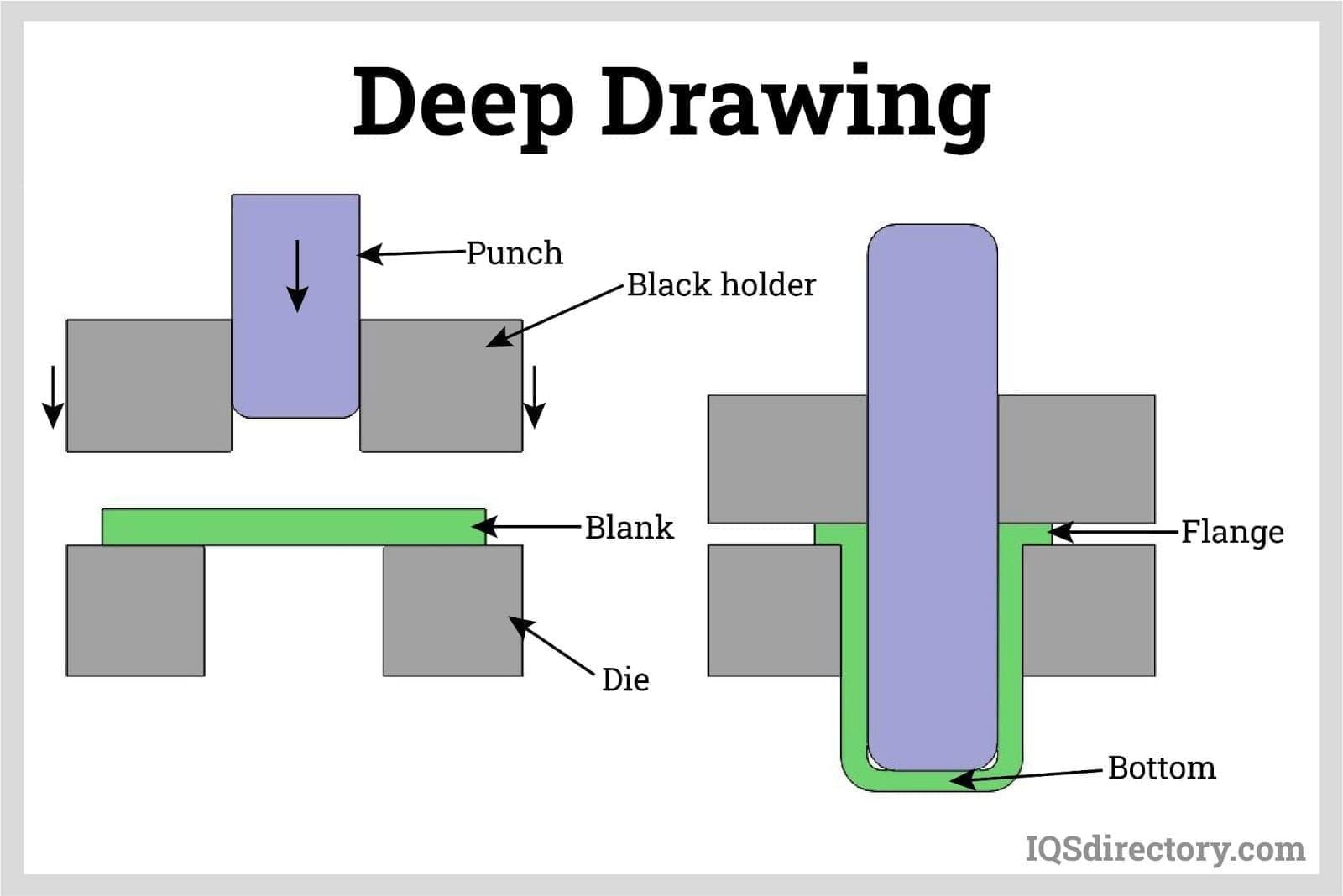

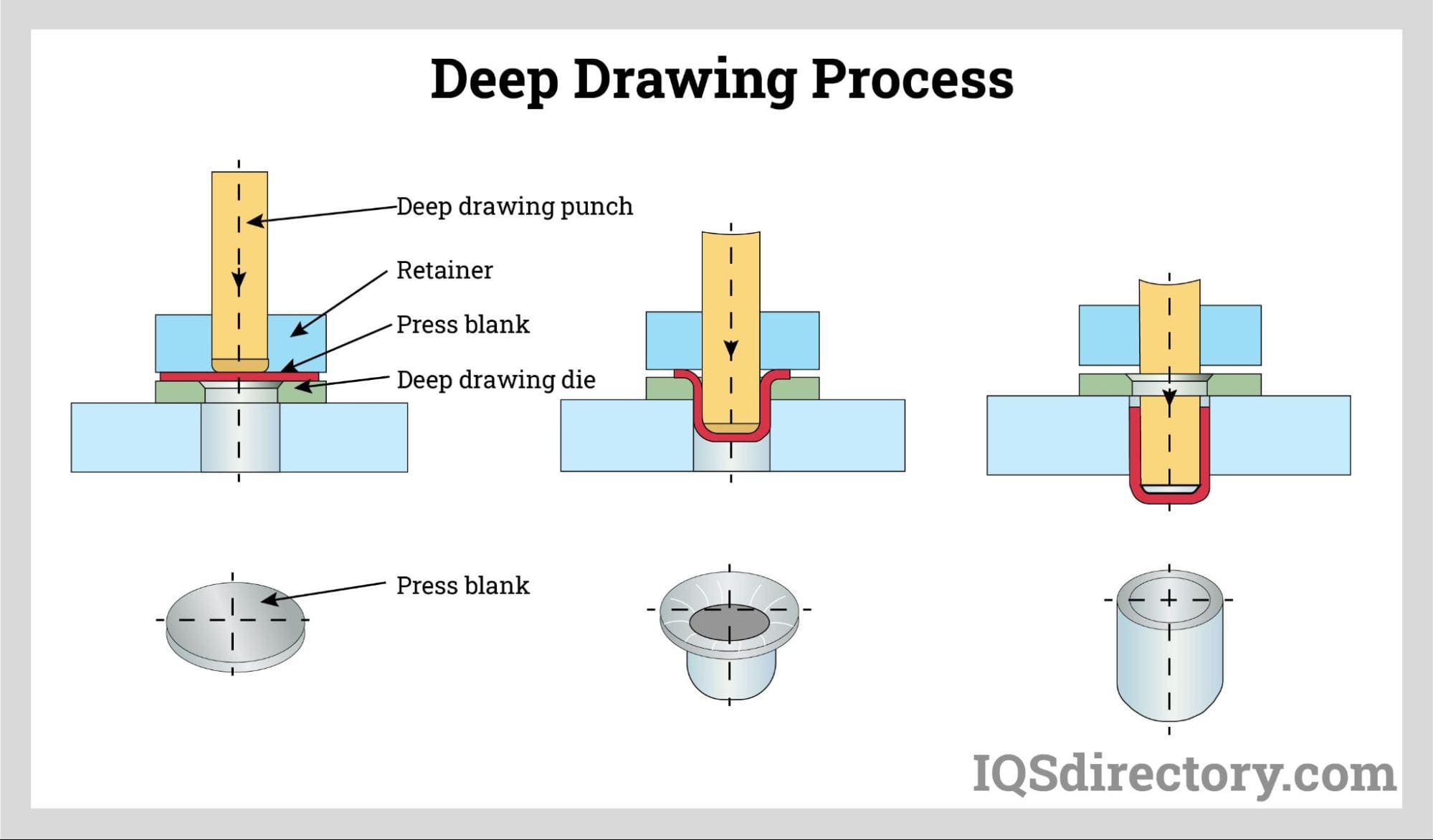

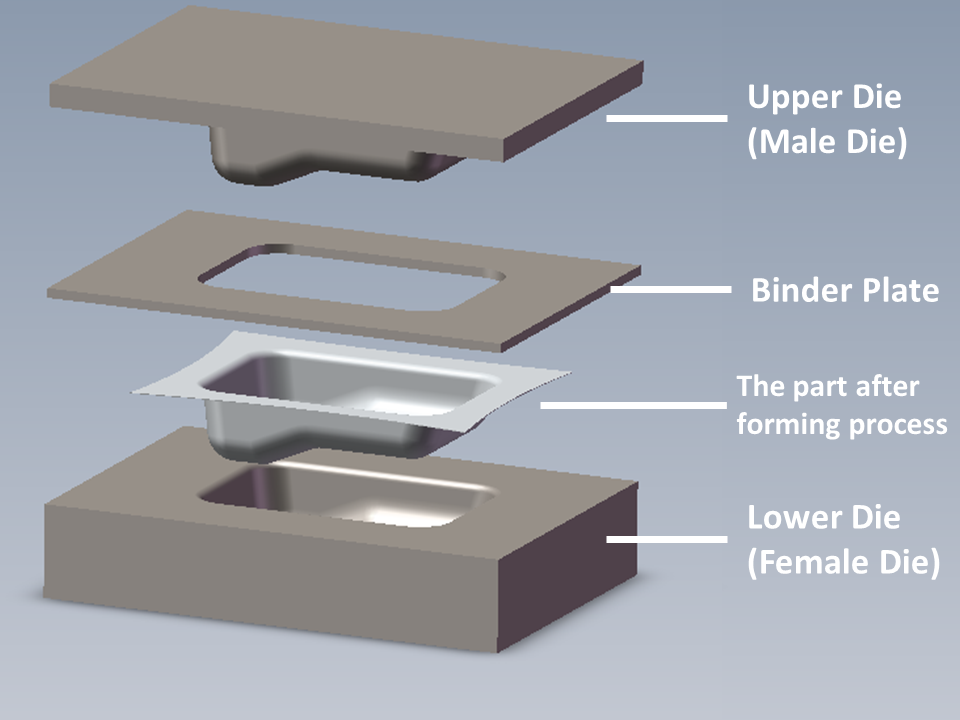

Drawing Stamping - This is the fifth in a series of articles presenting the fundamentals of stamping die design and construction. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Because deep draw stamping can create specialized parts, it requires manufacturers who have experience in this precise process. 5 applications of stamping process. All students have to do to enter the contest is to draw a picture of a native duck, goose, or swan, of a certain size and format, and submit it to their state's receiving site (for indiana that is muscatatuck nwr) by. Part xvi of this series wrapped up the discussion of bending in stamping operations. Don’t draw it, stamp it. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Deep draw stamping, a cornerstone in the manufacturing world, has revolutionized the way we produce intricate metal components. Web enhance your metal stamping and die design skills with our comprehensive guide on deep drawing. 553 views 9 months ago. Key elements in deep drawing. Deep draw metal stamping, in particular, has emerged as one of the most popular types, offering unique capabilities for creating. What are the types of deep drawing. “they’re beautiful singers,” lennon said. Press speed (ram speed) draw radii. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Showcase your talent and win big in artists network prestigious art competitions! Part xvi of this series wrapped up the discussion of bending in stamping operations. Web stamping transforms. Web enhance your metal stamping and die design skills with our comprehensive guide on deep drawing. Web the process of deep draw stamping. Web the wyoming game and fish department extends congratulations to the winners of the collectible conservation stamp art show. Part xvi of this series wrapped up the discussion of bending in stamping operations. All students have to. Drawing is a metal forming process in which the flow of material over a. Deep draw metal stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. Web the process of deep draw stamping. Every deep draw metal stamping process starts with. A blank piece of sheet metal is positioned over a die, and a punch is used to force the metal into the die and create a custom shape. Don’t draw it, stamp it. Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an exceptional degree of accuracy and repeatability. Deep draw metal. Drawing is a metal forming process in which the flow of material over a. Because deep draw stamping can create specialized parts, it requires manufacturers who have experience in this precise process. “they’re beautiful singers,” lennon said. Web stamping transforms flat sheet metal, also known as blanks, into any desired shape by using either hot or cold rolled sheets of. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: 4 what are the different stamping operations. A fast and fun way to create your next drawing. Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an. This article focuses on drawing. Web what is deep draw stamping? The deep draw process is necessary for parts with a depth that exceeds their diameter, like beverage cans, deep pans, assembly housings, and other containers. Cylindrical deep drawn aluminum cans are typical deep drawing applications. The process is considered deep drawing when the depth of the drawn part exceeds. “they’re beautiful singers,” lennon said. Deep draw stamping, a cornerstone in the manufacturing world, has revolutionized the way we produce intricate metal components. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. As industries evolve, the significance of this technique only grows, making it imperative for professionals and enthusiasts alike to grasp its nuances. The. All students have to do to enter the contest is to draw a picture of a native duck, goose, or swan, of a certain size and format, and submit it to their state's receiving site (for indiana that is muscatatuck nwr) by. A fast and fun way to create your next drawing. “they’re beautiful singers,” lennon said. It is thus. The three steps to deep draw metal stamping are as follows: This process involves the following main types of dies: Don’t draw it, stamp it. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Because deep draw stamping can create specialized parts, it requires manufacturers who have experience in this precise process. Web by art hedrick. This process forms the metal into the final shape. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression exerted on the metal during the forming process. However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation to understand and troubleshoot. Key elements in deep drawing. Drawing is a metal forming process in which the flow of material over a. Web stamping transforms flat sheet metal, also known as blanks, into any desired shape by using either hot or cold rolled sheets of steel. Web the wyoming game and fish department extends congratulations to the winners of the collectible conservation stamp art show. Learn the process, techniques, and tips for successful metal forming. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Web deep draw stamping is a type of sheet metal forming that allows manufacturers to draw flat sheet metal into a die and then create the desired components.

Tools for Deep Draw Metal Stampings Important Facts by PMP

Deep Drawn Stamping Companies Deep Drawn Stamping Services

How to draw Stamp YouTube

Deep Draw Stamping The Ultimate FAQ Guide CNstamping

Deep Drawn Stamping Companies Deep Drawn Stamping Services

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

Stamping Die Essentials Deep drawing

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep Drawing Stamping Introduction YouTube

What Is the Difference Between Drawing and Stamping? Ulbrich

A Blank Piece Of Sheet Metal Is Positioned Over A Die, And A Punch Is Used To Force The Metal Into The Die And Create A Custom Shape.

“They’re Beautiful Singers,” Lennon Said.

It Is Thus A Shape Transformation Process With Material Retention.

5 Applications Of Stamping Process.

Related Post: