Drawing Fiber

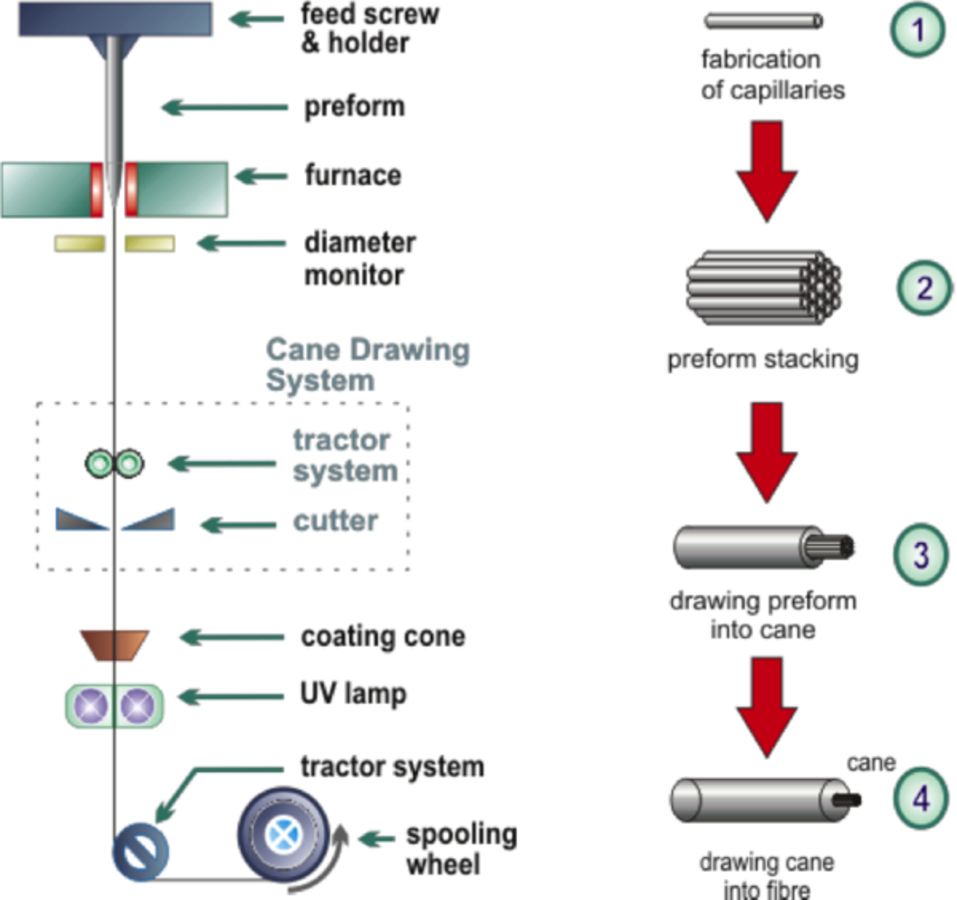

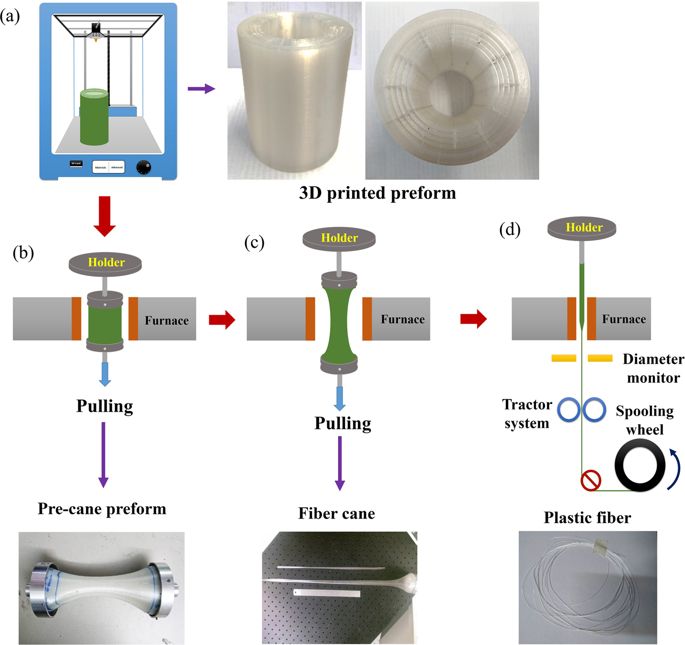

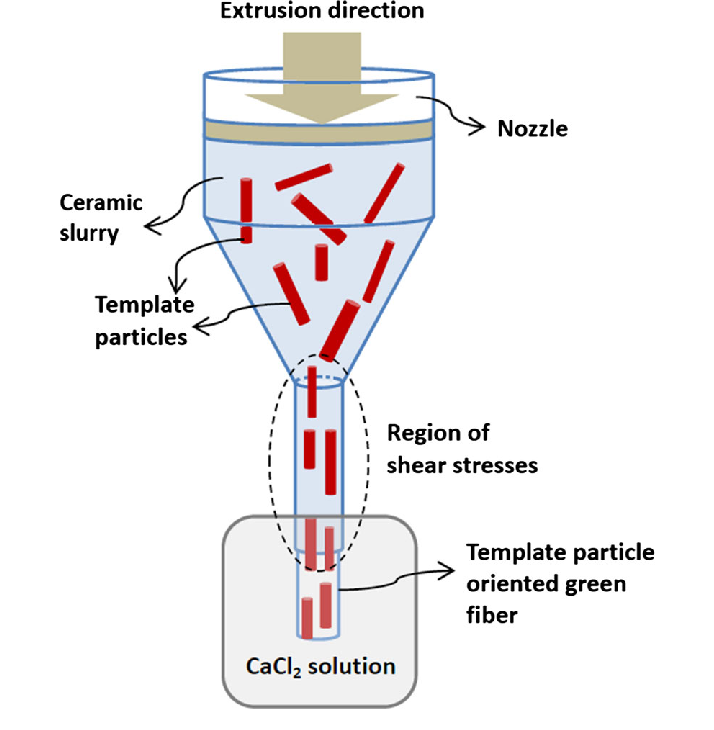

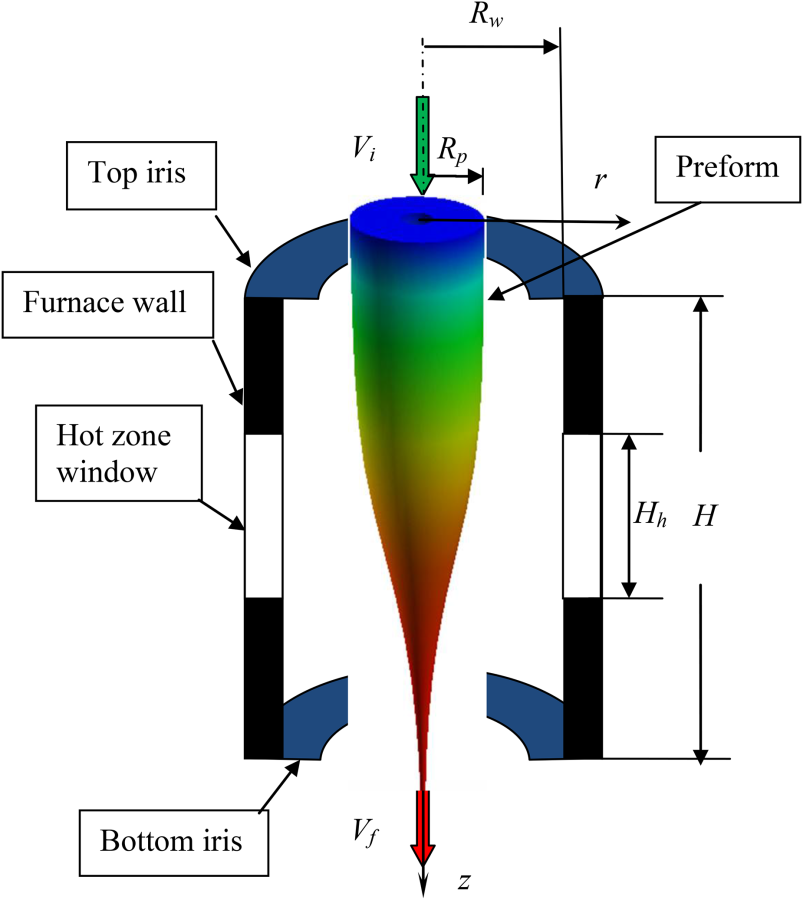

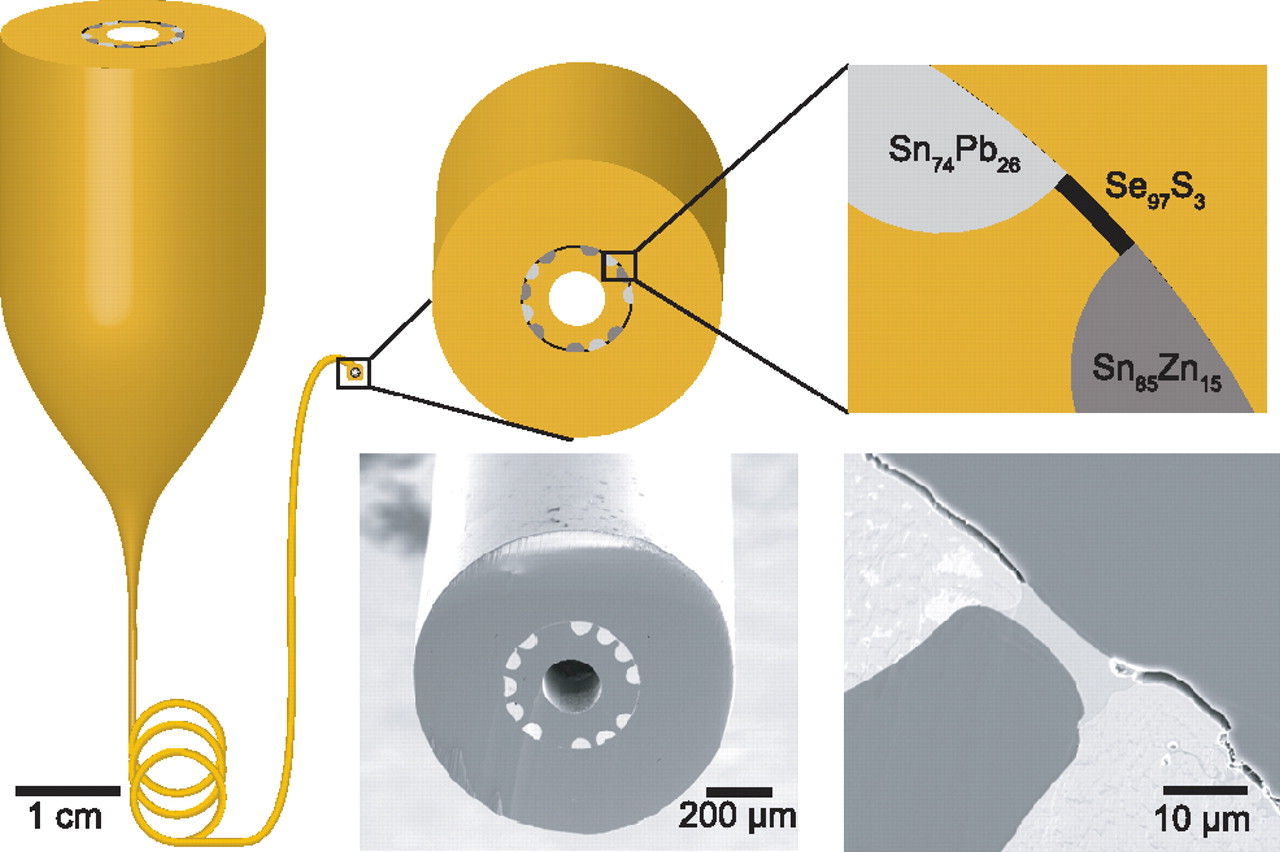

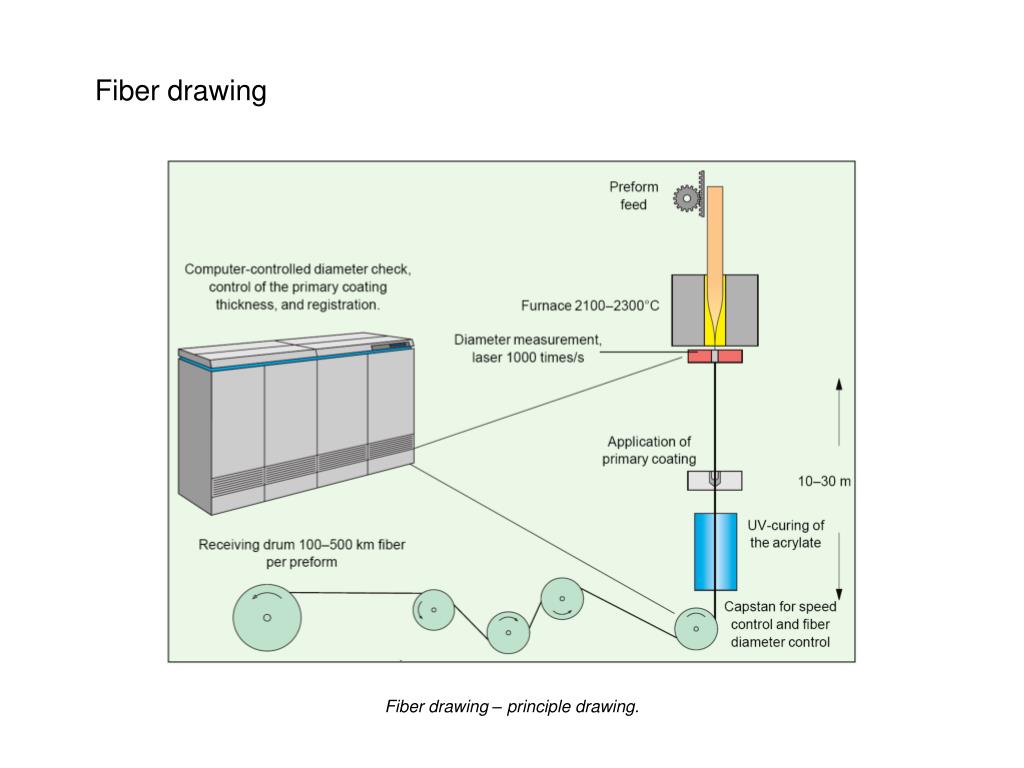

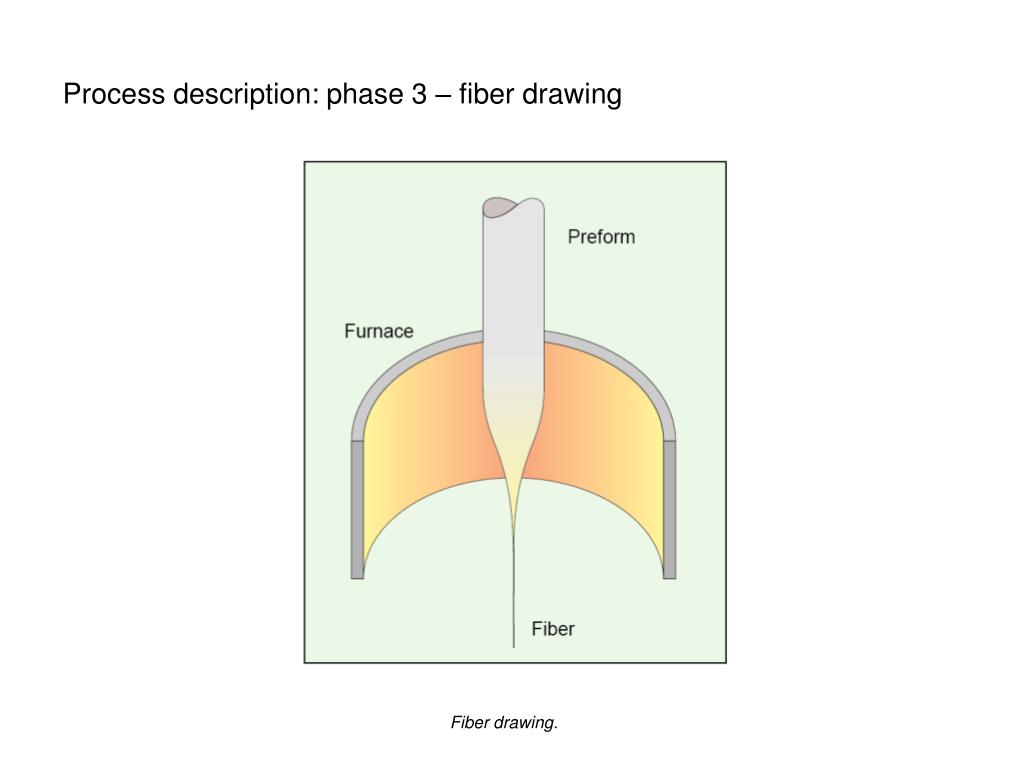

Drawing Fiber - A primary consideration is that crystalline disorder, and impurity segregation at the grain. New frontier of flexible electronics. Draw down itself indicates the characteristic that the fiber has been made thinner due to the drawing process; New methods of increasing both the structural complexity of fibers and number of materials compatible with the drawing process are substantially expanding the functionality of photonic crystal and. This process is critical in the production of fibers that are essential for telecommunications, medical imaging, and data transmission. Like everyone else with this capability, we can maximize production efficiency, converting production output into product as the fiber comes off the collection drum. Over 100 artworks by 60 different artists. 498 views 2 years ago. In specialty fiber factories, draw tower heights typically range from 7 to 14 meters. Web drawn fiber is an enhanced monofilament fiber obtained from polymer extrusion. Each pair of rollers spins faster than the previous one. Web manufacture of optical fibers: May 17, at artwrkd in partnership with triple sun spirits newtown. Author links open overlay panel. The basic transport mechanisms that arise are discussed, along with results from analytical, numerical, and experimental studies. This process is critical in the production of fibers that are essential for telecommunications, medical imaging, and data transmission. Web the golden thread: Each pair of rollers spins faster than the previous one. Web learn knitting, weaving, spinning (a twisting technique to form yarn), and crocheting with all the materials at your disposal. Like everyone else with this capability, we. Fti is a vertically integrated company drawing glass (borosilicate, leaded and unleaded) fiber in north america. A primary consideration is that crystalline disorder, and impurity segregation at the grain. Web how to draw optical fiber diagram? Web creating fibers comprised of conductors and piezoelectric materials allows for the realization of acoustoelectric fiber devices. Web drawing, in yarn manufacture, process of. Web drawn fiber is an enhanced monofilament fiber obtained from polymer extrusion. This process is done by passing them through the furnace and pulling them from the other end. Telecom fiber manufacturers aim draw at higher speeds to achieve bulk production. Web thermally drawn advanced functional fibers: In specialty fiber factories, draw tower heights typically range from 7 to 14. , chaoqun dong 2 †. A primary consideration is that crystalline disorder, and impurity segregation at the grain. Web drawn fiber is an enhanced monofilament fiber obtained from polymer extrusion. Web manufacture of optical fibers: Web the golden thread: Thermally drawn advanced functional fibers: Web this chapter discusses the fabrication of optical fibers, focusing on the drawing, cooling, and coating of fibers. Web thermal fiber drawing is a process in which a macrostructured preform is heated and drawn into extended lengths of microstructured fiber. Web from the fiber structure point of view, the nature of the fiber drawing process. Thermally drawn advanced functional fibers: A primary consideration is that crystalline disorder, and impurity segregation at the grain. Each pair of rollers spins faster than the previous one. New methods of increasing both the structural complexity of fibers and number of materials compatible with the drawing process are substantially expanding the functionality of photonic crystal and. Web thermally drawn advanced. Amanda phingbodhipakkiya’s “rest is a. Web thermal fiber drawing is a process in which a macrostructured preform is heated and drawn into extended lengths of microstructured fiber. Each pair of rollers spins faster than the previous one. Expect three sessions for the beginners class. Optical fiber structure, types of fiber. Fti is a vertically integrated company drawing glass (borosilicate, leaded and unleaded) fiber in north america. Web fiber drawing is a manufacturing process used to create optical fibers, which are thin strands of glass or plastic used to transmit light signals over long distances. Web the golden thread: Web drawn fiber is an enhanced monofilament fiber obtained from polymer extrusion.. Web thermal fiber drawing is a process in which a macrostructured preform is heated and drawn into extended lengths of microstructured fiber. This process is done by passing them through the furnace and pulling them from the other end. Like everyone else with this capability, we can maximize production efficiency, converting production output into product as the fiber comes off. This ticketed event is from 6:30 to 9:30 p.m. Web it will be an immersive experience within the fiber art exhibition, inviting both artists and the audience to explore the limitless possibilities of textiles. In specialty fiber factories, draw tower heights typically range from 7 to 14 meters. Web how to draw optical fiber diagram? , chaoqun dong 2 †. Fti is a vertically integrated company drawing glass (borosilicate, leaded and unleaded) fiber in north america. Like everyone else with this capability, we can maximize production efficiency, converting production output into product as the fiber comes off the collection drum. This process is critical in the production of fibers that are essential for telecommunications, medical imaging, and data transmission. Each pair of rollers spins faster than the previous one. Web creating fibers comprised of conductors and piezoelectric materials allows for the realization of acoustoelectric fiber devices. Web drawing, in yarn manufacture, process of attenuating the loose assemblage of fibres called sliver ( q.v.) by passing it through a series of rollers, thus straightening the individual fibres and making them more parallel. 498 views 2 years ago. Web the golden thread: Thermally drawn multimaterial fibers have experienced rapid development in the past two decades owing to the high scalability, uniformity, and material and structure compatibility of the thermal drawing technique. New frontier of flexible electronics. Web drawn fiber is an enhanced monofilament fiber obtained from polymer extrusion.

Fibre Fabrication

Fiber Drawing at Explore collection of Fiber Drawing

Fiber Drawing at Explore collection of Fiber Drawing

Fiber Drawing at Explore collection of Fiber Drawing

Polymer fiber drawing process, illustrating a reduction of preform

Fiber Drawing at Explore collection of Fiber Drawing

(a) Schematic of the fiber drawing process; (b) Photograph of the

PPT Chapter 3 Preform manufacture and fiber drawing PowerPoint

Fiber drawing apparatus. Download Scientific Diagram

PPT Chapter 3 Preform manufacture and fiber drawing PowerPoint

Web Thermal Fiber Drawing Is A Process In Which A Macrostructured Preform Is Heated And Drawn Into Extended Lengths Of Microstructured Fiber.

Draw Down Itself Indicates The Characteristic That The Fiber Has Been Made Thinner Due To The Drawing Process;

, Yuanzhuo Xiang 3 †.

This Process Is Done By Passing Them Through The Furnace And Pulling Them From The Other End.

Related Post: